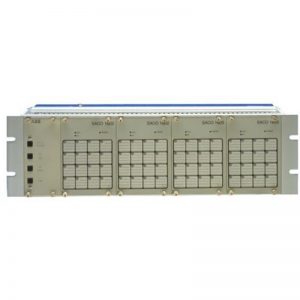

ABB UCD240A101 3BHE022287R0101

¥5,255.00

Module Number: UCD240A101 3BHE022287R0101

Product status: Discontinued

Delivery time: In stock

Product status: 100% new

Sales country: All over the world

Product situation: one year warranty

Contact me: Sauldcsplc@gmail.com +8613822101417 SIMON

Have a good day! Thanks for watching my website!

ZYGO ZMI-2002 8020-0211

GE SR469-P5-HI-A20

BENTLY 3500/33 149986-01

HIMA X-AI3201 985210213

HIMA X-DI3201 985210201

HIMA X-DO2401 985210203

HONEYWELL 05701-A-0361

Description

ABB UCD240A101 3BHE022287R0101

- .Many products are not yet on the shelves please contact us for more products

- .If there is any inconsistency between the product model and the picture on display, the model shall prevail. Contact us for the specific product picture, and we will arrange to take photos in the warehouse for confirmation

- .We have 16 shared warehouses around the world, so please understand that it can sometimes take several hours to accurately return to you. Of course, we will respond to your concerns as soon as possible

UCD240A101 3BHE022287R0101 Step 1: Tool preset

An RFID tag is embedded and installed on the handle of the tool, and the tool presetter with built-in RFID reading and writing unit automatically knows the inserted tool through the tool number. After binding, each tool can be tracked to ensure that the tool is in good condition.

Step 2: Measure parameters

The RFID reading and writing head installed on the machine tool, tool magazine, and tool alignment instrument can recognize the RFID tags on the tools, obtain key parameters based on the current process, and write them in real time into the RFID tags on the tool holder.

Step 3: Adjust parameters

After the UCD240A101 3BHE022287R0101 tool information is read and written, the CNC machining center can adjust the component parameters of CNC machining in real time according to the tool condition, achieving precise machining and timely repair of the tool, ensuring the ideal use of the tool.

Step 4: Record losses

After the tool is processed, the corresponding loss information can be updated in the tool alignment instrument through RFID and transmitted back to the tool library

-

Please contact us for the best price. Email: 【sauldcsplc@gmail.com】

-

For more products, click here

Mailbox:sauldcsplc@gmail.com | UCD240A101 3BHE022287R0101

www.abbgedcs.com | Qiming Industrial Control | Simon +86 13822101417

Reviews

There are no reviews yet.