330100-90-00 | BENTLY | Zero Point C Series Distributed IO

¥8,744.00

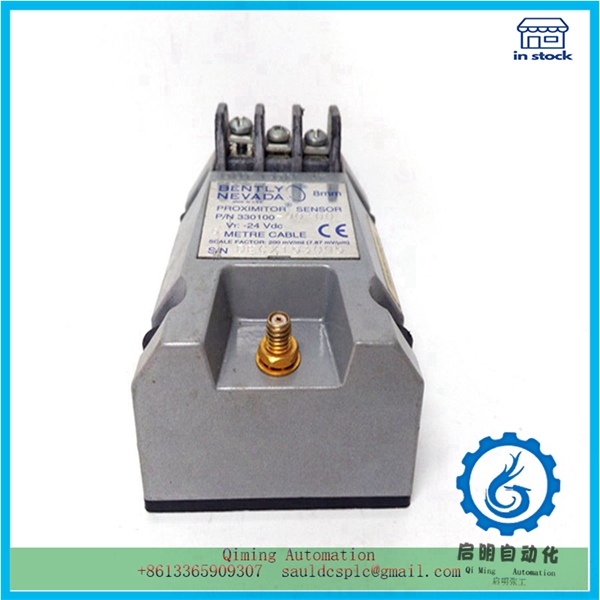

Module Number: 330100-90-00

Product status: Discontinued

Delivery time: In stock

Sales country: All over the world

Product situation: Brandnew , one year warranty

Contact me: Sauldcsplc@gmail.com +8613822101417 SIMON

Have a good day! Thanks for watching my website!

Introduced Product:

PFSA103D 3BSE002492R0001

3BHB009884R5211

S-073N 3BHB009884R0021

GFD563 3BHE046836R0101

1200MM-ST630 700米

PM891K01 3BSE053241R1

PPD512 A10-454000

AC800M 3BSE053240R1 PM891

PPD512 A10-454000

H90QHQE013N0

3009X

PM891K01

3009

9907-164

Description

330100-90-00 | BENTLY | Zero Point C Series Distributed IO

- .Many products are not yet on the shelves please contact us for more products

- .If there is any inconsistency between the product model and the picture on display, the model shall prevail. Contact us for the specific product picture, and we will arrange to take photos in the warehouse for confirmation

- .We have 16 shared warehouses around the world, so please understand that it can sometimes take several hours to accurately return to you. Of course, we will respond to your concerns as soon as possible

With the continuous development of human society and industrial modernization, the problem of water resource shortage is becoming increasingly serious. Optimizing and implementing automated control of urban domestic sewage treatment processes has profound theoretical significance and practical value in improving sewage treatment efficiency, saving funds, and improving environmental quality.

The process flow of sewage treatment can be roughly divided into pre-treatment, biochemical treatment, and deepening treatment. In the process of upgrading and renovating sewage treatment plants, technological innovation is crucial. The transformation and upgrading of the industry cannot be separated from the guarantee and support of new technologies and high-tech.

The sewage treatment plant adopts Siemens 1500 as the main control PLC, located in the central control room, and uses the Zero Point ES series switch to build a ring network platform. Each process section uses the CN-8032-L module as the slave station, and data collection and control of the process section are achieved through IO. The control is transmitted to the PLC through the connection to the ring network switch.

The process section includes:

1. Preprocessing section: This section sets up a CN-8032-L as the slave station. The pre-treatment section includes the control of coarse and fine grids and the aeration sedimentation tank. Remote start stop control of the grids is achieved through the CT-121F module and the CT-222F module. The aeration sedimentation tank is provided by a complete set of equipment manufacturers, with a 485 interface provided externally and supporting the standard Modbus RTU protocol. Monitoring is achieved through communication with the aeration sedimentation tank using the CT-5321 module, and linkage is achieved with the inlet and grid.

2. Carbon source addition room: In order to ensure that the total nitrogen emissions meet the standards, the amount of total nitrogen in wastewater is reduced by adding a carbon source. This process section is equipped with multiple flow meters and on/off valves to achieve automatic configuration of the chemical solution. CN-8032-L is also set as a slave station at the station, and the CT-121F module and CT-222F module are used to control the on/off valves. The PNM02 V2.0 gateway is used to collect the instantaneous flow and cumulative flow of 8 sets of flow meters on site, After connecting to the ring network, it is directly transmitted to the PLC.

Mailbox:sauldcsplc@gmail.com | 07KT98 GJR5253100R427807KT98 H3

www.abbgedcs.com | Qiming Industrial Control | Simon +86 13822101417

Reviews

There are no reviews yet.