8101-HI-TX-02 | GE | Detailed process parameters

¥4,778.00

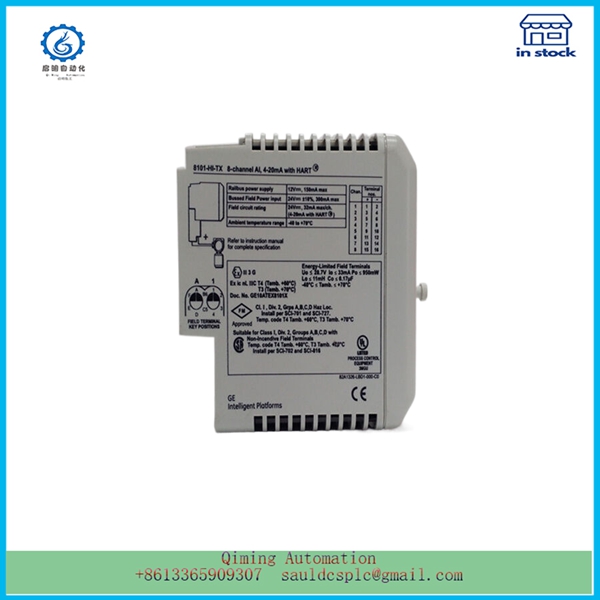

Module Number: 8101-HI-TX-02

Product status: Discontinued

Delivery time: In stock

Sales country: All over the world

Product situation: Brandnew , one year warranty

Contact me: Sauldcsplc@gmail.com +8613822101417 SIMON

Have a good day! Thanks for watching my website!

Description

8101-HI-TX-02 | GE | Detailed process parameters

- .Many products are not yet on the shelves please contact us for more products

- .If there is any inconsistency between the product model and the picture on display, the model shall prevail. Contact us for the specific product picture, and we will arrange to take photos in the warehouse for confirmation

- .We have 16 shared warehouses around the world, so please understand that it can sometimes take several hours to accurately return to you. Of course, we will respond to your concerns as soon as possible

8101-HI-TX-02 we have:

We provide considerate service and complete parts

① Promptly reply you within 24 hours;

② 100% quality assurance, 1-year warranty;

③ Best services, reasonable price;

④ Have been in the line for many years, has a good reputation;

⑤ We will ship the items within 3 working days after the payment is reached;

⑥ All the goods will be tested before shipment;

⑦ Packing in professional anti-static bag;

1.1 Theoretical value of drilling hole diameter=nominal diameter of component pins+twice the thickness of metalized hole wall+twice the thickness of component pin tin coating+drilling hole diameter error+component pin diameter error.

In actual design, first measure the nominal diameter of the component pins, 8101-HI-TX-02 (usually circular leg diameter, square leg diagonal), and then add 0.1-0.2mm as the finished hole diameter provided to the manufacturer.

1.2 If the pins of the device are rectangular, they should be arranged in a row of drills; Some design software does not provide the function of setting drilling arrangement, which should be noted at the machining level (as shown in Figure 1). The length/width ratio of drilling arrangement should not be too small, should be greater than 2:1, and the minimum size should not be less than 32mil (0.8mm).

1.3 If the device is a crimped device, it should be specifically noted in the description that the hole of the crimped device should meet the requirement of negative aperture tolerance to ensure the reliability of the plug-in device;

1.4 Installation holes: (including threading holes or other loose holes) should be provided in the form of solder pads for hole positions and apertures. Installation holes are divided into metalized and non-metallic types. Non metalized holes must be unchecked with the metallization attribute option in the solder pad option (as shown in Figure 2). 8101-HI-TX-02 Note that device holes must not be selected with this option, otherwise each layer will not be able to conduct;

The minimum finished hole diameter for 1.5 through holes is 4mil (0.1mm). Under the condition of allowable wiring spacing, the recommended value of through-hole aperture is (12-20mil) 0.3-0.5mm to ensure the quality of metalization of the hole wall inside the hole. If there is a requirement for through-hole tin plating, the minimum aperture of the through-hole is (12-20mil) 0.3-0.5mm.

-

Please contact us for the best price. Email: 【sauldcsplc@gmail.com】

-

For more products, click here

Mailbox:sauldcsplc@gmail.com |8101-HI-TX-02

www.abbgedcs.com | Qiming Industrial Control | Simon +86 13822101417

Reviews

There are no reviews yet.