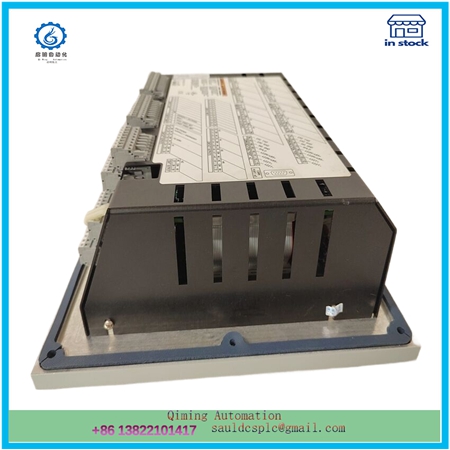

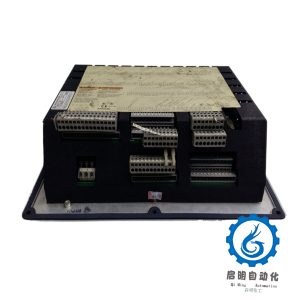

9907-164 | WOODWARD | digital microprocessor controller

¥3,544.00

🔔Module Number: 9907-164

⚠️Product status: Discontinued

🏚️Delivery time: In stock

🆕Product status: 100% new

🌍Sales country: All over the world

🥇Product situation: one year warranty

📮Contact me: Sauldcsplc@gmail.com

💬Wechat/Whatsapp :+86 13822101417

☀️Have a good day! Thanks for watching my website!

Description

The WOODWARD 9907-164 controller is a digital microprocessor controller module manufactured and designed by Woodward, widely used in industrial control systems, especially for the operation of equipment such as steam turbines, turbine generators, and turbine expanders. The following is a detailed introduction to the WOODWARD 9907-164 controller:

1、 Basic Overview

Type: Digital microprocessor controller module, also known as electro-hydraulic converter or turbine control module.

Manufacturer: Woodward Corporation.

Application areas: industrial automation, power generation control systems, steam turbines, gas turbines, and hydro turbines, etc.

2、 Main functions

Electro hydraulic conversion function:

Capable of converting electrical signals into hydraulic or pneumatic signals for controlling actuators, valves, hydraulic cylinders, and other equipment.

Supports specific voltage or current input ranges, and can configure the pressure or flow range of the output signal according to application requirements.

Turbine control function:

Can be used for different types of turbines for speed control, load control, compressor and turbine start and stop control, etc.

Control the steam turbine by operating the single extraction and/or intake of the turbine, using the turbine’s split actuator to drive the steam inlet valve.

Monitoring and control parameters:

Monitor the voltage, current, frequency and other parameters of the generator set to ensure its stable operation.

Collect and monitor data related to turbine performance, such as speed, temperature, pressure, etc., to ensure that the turbine operates within a safe and effective operating range.

Fault detection and protection:

Implement fault detection and protection strategies, monitor abnormal situations in the system, and trigger corresponding protection actions.

Being able to detect turbine faults and provide alerts, improving the reliability of the system.

Communication and data recording:

Equipped with communication interfaces such as RS-232/RS-422 (with Modbus protocol), Ethernet or fieldbus protocols (such as Profibus, Modbus), allowing data exchange and communication with other devices, upper computers or monitoring systems.

May have data recording capabilities for recording key parameters and events, facilitating troubleshooting, performance evaluation, and data analysis.

3、 Technical features

High precision and stability: Adopting high-precision design and manufacturing processes to ensure stable performance under various working conditions.

Programmable: Allow users to program as needed to achieve more complex control logic.

Self diagnosis and fault detection: Equipped with self diagnosis function, it can automatically detect potential problems and provide alerts.

Easy to operate: Provides an intuitive user interface, making it convenient for users to operate and monitor.

4、 Application examples

The WOODWARD 9907-164 controller is commonly used in industrial automation and power generation control systems, especially playing an important role in control systems involving steam turbines, turbine generators, and turbine expanders. It can help users achieve precise system control and monitoring, improve equipment operation efficiency and safety.

5、 Summary

The WOODWARD 9907-164 controller is a powerful, stable, and easy-to-use digital microprocessor controller module. It achieves precise control and monitoring of industrial equipment and generator sets through electro-hydraulic conversion and turbine control functions. At the same time, its high precision, programmability, self diagnosis, and fault detection characteristics make the controller have broad application prospects in industrial automation and power generation control systems.

Reviews

There are no reviews yet.