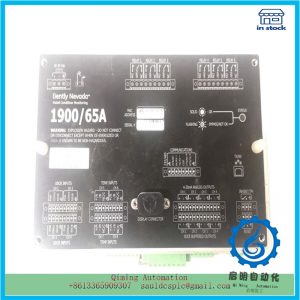

Bently Nevada 3500/22M communication processor

¥5,442.00

🔔Module Number: 3500/22M

⚠️Product status: Discontinued

🏚️Delivery time: In stock

🆕Product status: 100% new

🌍Sales country: All over the world

🥇Product situation: one year warranty

📮Contact me: Sauldcsplc@gmail.com

💬Wechat/Whatsapp :+86 13822101417

☀️Have a good day! Thanks for watching my website!

Description

Bently Nevada 3500/22M communication processor

- .Many products are not yet on the shelves please contact us for more products

- .If there is any inconsistency between the product model and the picture on display, the model shall prevail. Contact us for the specific product picture, and we will arrange to take photos in the warehouse for confirmation

- .We have 16 shared warehouses around the world, so please understand that it can sometimes take several hours to accurately return to you. Of course, we will respond to your concerns as soon as possible

The 3500 Transient Data Interface (TDI) is the interface between the 3500 monitoring system and Bently Nevada’s System 1® machinery management software. The TDI combines the capability of a 3500/20 Rack Interface Module with the data collection capability of a communication processor such as TDXnet. TDI operates in the RIM slot of a 3500 rack in conjunction with the M series monitors (3500/40M, 3500/42M, etc.) to continuously collect steady state and transient waveform data and pass this data through an Ethernet link to the host software. Static data capture is standard with the TDI, however using an optional Channel Enabling Disk will allow dynamic or transient data to be captured as well. TDI has made improvements in several areas over previous communication processors in addition to incorporating the Communication Processor function within the 3500 rack. TDI provides certain functions common to the entire rack, however the TDI is not part of the critical monitoring path and has no effect on the proper, normal operation of the overall monitor system. One TDI or RIM is required per rack. The TDI occupies only a single slot in the rack and is always located in Slot 1 (next to the power supplies). For Triple Modular Redundant (TMR) applications, the 3500 System requires a TMR version of the TDI. In addition to all the standard TDI functions, the TMR TDI also performs “monitor channel comparison”. The 3500 TMR configuration executes monitoring voting using the setup specified in the monitor options. Using this method, the TMR TDI continually compares the outputs from three (3) redundant monitors. If the TMR detects that the information from one of those monitors is no longer equivalent (within a configured percent) to the remaining two, it will flag the monitor as being in error and place an event in the System Event List.

3500/22M Specifications Inputs Power Consumption 10.5 Watts Data Front panel: 115.2 kbaud maximum RS232 serial communications 10 Base-T/100 Base-TX I/O: 10 Base-T or 100 Base-TX Ethernet, autosensing 100 Base-FX I/O: 100 Base-FX Fiber-Optic Ethernet Outputs Front Panel LEDs OK LED: Indicates when the 3500/22M is operating properly TX/RX LED: Indicates when the 3500/22M is communicating with the other modules in the rack. TM LED: Indicates when the 3500 rack is in Trip Multiply mode. CONFIG OK LED: Indicates that the 3500 rack has a valid configuration. I/O Module OK Relay: Relay to indicate when the 3500 rack is operating normally or when a fault has been detected within the rack. User can select either an “OPEN” or “CLOSED” contact to annunciate a NOT OK condition. This relay always operates as “Normally Energized”. OK Relay: Rated to 5A @ 24 Vdc/120 Vac, 120 Watts/600 VA Switched Power. Normally closed contacts: Arc suppressors are provided. Controls Front Panel Rack reset button: Clears latched alarms and Timed OK Channel Defeat in the rack. Performs same function as “Rack Reset” contact on I/O module. Address switch: Used to set the rack address: 127 possible addresses. Configuration Keylock: Used to place 3500 rack in either “RUN” mode or “PROGRAM” mode. RUN mode allows for normal operation of the rack and locks out configuration changes. PROGAM mode allows for normal operation of the rack and also allows for local or remote rack configuration. The key can be removed from rack in either position, allowing switch to remain in either RUN or PROGRAM position. Locking switch in the RUN position allows you to restrict unauthorized rack reconfiguration. Locking switch in PROGRAM position allows remote reconfiguration of a rack at any time. I/O Module System Contacts Trip Multiply: Description: Used to place 3500 rack in Trip Multiply. Maximum Current: <1 mAdc, Dry Contact to Common Alarm Inhibit: Description: Used to inhibit all alarms in the 3500 rack. Maximum Current: <1 mAdc, Dry Contact to Common Rack Reset: Description: Used to clear latched alarms and Timed OK Channel Defeat. Maximum Current: <1 mAdc, Dry Contact to Common

Please contact us for the best price. Email: 【sauldcsplc@gmail.com】

-

For more products, click here

Mailbox:sauldcsplc@gmail.com | 3500/22M

www.abbgedcs.com | Qiming Industrial Control | Simon +86 13822101417

Reviews

There are no reviews yet.