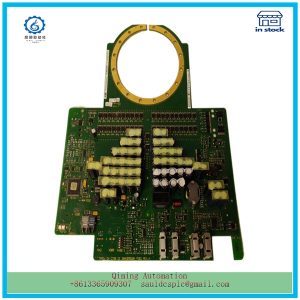

FLOWSERVE CORPORATION Board 64-825-0045-4

¥1,450.00

🔔Module Number: 64-825-0045-4

⚠️Product status: Discontinued

🏚️Delivery time: In stock

🆕Product status: 100% new

🌍Sales country: All over the world

🥇Product situation: one year warranty

📮Contact me: Sauldcsplc@gmail.com

💬Wechat/Whatsapp :+86 13822101417

☀️Have a good day! Thanks for watching my website!

Description

The **Flowserve Corporation MXA FF PA Board** with part number **64-825-0045-4 Rev 2.0** is a component typically used in the context of control systems for fluid handling and processing applications. Flowserve specializes in various equipment and systems used in pumps, valves, seals, and automated controls, often serving industries such as oil and gas, water management, and chemical processing.

### Key Features and Functions:

1. **Control Functionality**:

– The MXA FF PA Board is likely designed for process automation, specifically to improve control over fluid dynamics and associated parameters within a system.

2. **Signal Processing**:

– It may include capabilities to process input signals from various sensors and control elements, allowing for precise management of flow rates, pressures, and other critical process variables.

3. **Integration with Control Systems**:

– This board might be part of a larger control system architecture, enabling coordinated operations among multiple components like pumps, valves, and monitoring systems.

4. **User Interface**:

– Depending on the design, it may also provide interfaces for operators to monitor system performance, adjust parameters, and receive diagnostic feedback.

5. **Fault Monitoring**:

– Advanced boards typically include features for fault detection and diagnostics. This can help in identifying issues within the system, reducing downtime, and facilitating maintenance.

Installation and Maintenance:

1. **Installation**:

– Follow the specific installation guidelines provided in the technical manual for the MXA FF PA Board to ensure proper integration into the system.

2. **Configuration**:

– After installation, configuration may be required according to the operational needs and specifications of the application.

3. **Testing**:

– Conduct functional tests post-installation to ensure that all control features and interfaces are working correctly, checking for responsiveness and accuracy.

4. **Regular Maintenance**:

– Implement a routine maintenance schedule that includes checking connections, verifying functionality, and updating any software or firmware as applicable.

5. **Documentation**:

– Maintain comprehensive records of installation, configuration, and maintenance practices. This may assist in future troubleshooting and compliance with industry standards.

### Resources for Further Information:

1. **User Manual**: Always refer to the specific user manual or datasheet for part number 64-825-0045-4 Rev 2.0 for detailed information on its specifications, wiring diagrams, and operational guidelines.

2. **Flowserve Support**: If you have technical questions or need troubleshooting assistance, contacting Flowserve’s customer support or technical service department can be beneficial.

3. **Training and Certification**: Consider exploring training options offered by Flowserve or industry organizations focused on fluid handling systems and control technologies.

4. **Professional Community**: Engaging with professionals and forums related to fluid dynamics and control systems can provide shared insights and best practices from users who have experience with similar components.

If you have specific questions or need additional information about the Flowserve MXA FF PA Board or its applications, feel free to ask!

_副本-300x300.jpg)

Reviews

There are no reviews yet.