FS7-2173-2RP | HONEYWELL | Carbon dioxide analyzer module

¥2,565.00

Module Number: FS7-2173-2RP

Product status: Discontinued

Delivery time: In stock

Sales country: All over the world

Product situation: Brandnew , one year warranty

Contact me: Sauldcsplc@gmail.com +8613822101417 SIMON

Have a good day! Thanks for watching my website!

Introduced Product:

KUKA KSD1-16

KUKA KSD1-08

KUKA 00-119-763

KUKA DSE-IBS 3.02

KUKA 1FK6081-6AF71-1ZZ9-Z

KUKA 00-132-349

KUKA PH1003-2840

Kawasaki 50999-2820

Keithley PDMA-32

Kollmorgen BJRL-20012-110001

LAM 853-001983-110

LAM 810-800081-018

LAM 810-800082-043

LAM 853-049542-173

Description

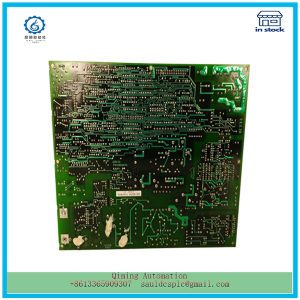

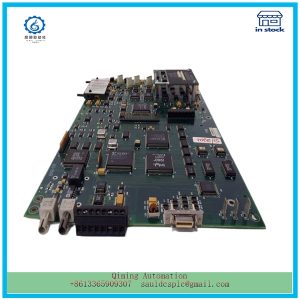

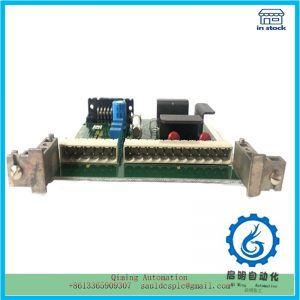

FS7-2173-2RP | HONEYWELL | Carbon dioxide analyzer module

The boiler FS7-2173-2RP safety monitoring FSSS can continuously and closely monitor a large number of parameters and states of the combustion system under various operating modes such as normal operation and start stop of the boiler, continuously make logical judgments and calculations, and issue action instructions when necessary. Through various sequential control and interlocking devices, the relevant equipment in the combustion system (such as coal mills, coal feeders, oil guns, flame detection cooling fans, etc.) Strictly follow a certain logical sequence for operation or handling near misses to ensure the safety of the boiler. At the same time, the furnace safety monitoring system also has a combustion management function. It controls the switching of burners on each layer of the boiler to meet the needs of unit start-up and load reduction. It continuously monitors the operating parameters and status of the boiler and automatically completes various operations and protection actions, such as emergency fuel supply cut-off and emergency shutdown, to prevent accidents from expanding.

The FS7-2173-2RP system of the steam turbine is mainly used to regulate the speed of the steam turbine and can complete the following functions: engaging the brake; Automatically determine the thermal state; Select the startup method; Speed increase; 3000rpm constant speed; Generator false synchronization test; Grid connected with load; Load increase; Valve switching; Switching between single valve and sequential valve; Pressure feedback of the regulating stage; Load feedback; Primary frequency modulation; CCS control; ATR thermal stress control; High load limit; Low load limit; Valve position limit; Main steam pressure limit; Quick unloading of load; Overspeed limit OPC; Conforming to imbalance; Overspeed protection OSP; Fuel injection test; Overspeed test; Valve activity test; Valve online tuning; Electromagnetic valve test; Control mode switching

Reviews

There are no reviews yet.