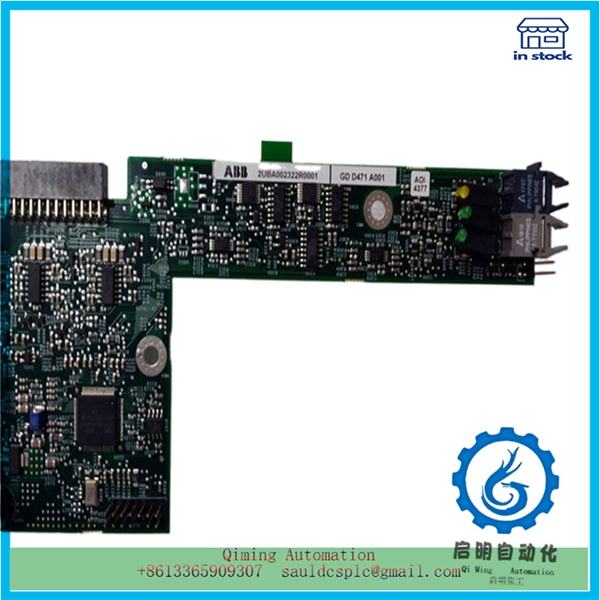

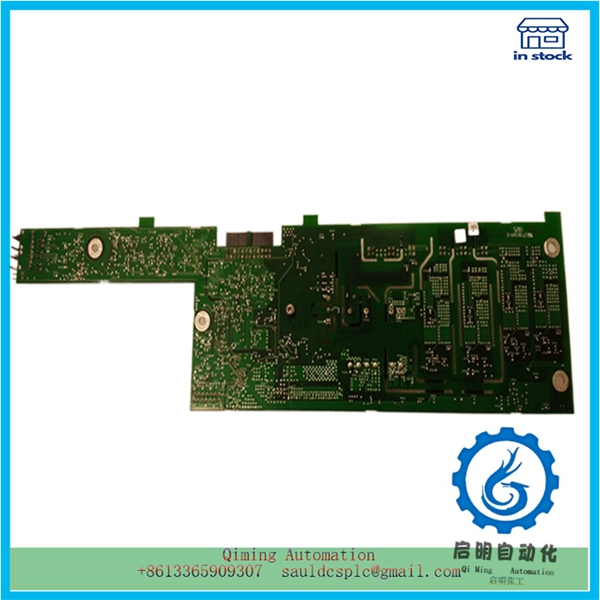

GDD471A001 2UBA002322R0001 2UBA002322R0003 | ABB | hydraulic system module

¥4,511.00

Module Number: GDD471A001 2UBA002322R0001

Product status: Discontinued

Delivery time: In stock

Sales country: All over the world

Product situation: Brandnew , one year warranty

Contact me: Sauldcsplc@gmail.com +8613822101417 SIMON

Have a good day! Thanks for watching my website!

Introduced Product:

BENTLY 3300/16-11-01-03-00-00-01

BENTLY 3300/20-12-01-03-00-00

BENTLY 84152-01

BENTLY 133819-02

BENTLY 3500/05-01-01-00-00-01

BENTLY 9200-01-01-10-00

BENTLY 3500/72M

Description

GDD471A001 2UBA002322R0001 2UBA002322R0003 | ABB | hydraulic system module

- .Many products are not yet on the shelves please contact us for more products

- .If there is any inconsistency between the product model and the picture on display, the model shall prevail. Contact us for the specific product picture, and we will arrange to take photos in the warehouse for confirmation

- .We have 16 shared warehouses around the world, so please understand that it can sometimes take several hours to accurately return to you. Of course, we will respond to your concerns as soon as possible

In recent years, the growing GDD471A001 for injection molded products in industries such as automobiles, construction, household appliances, food, and pharmaceuticals has further promoted the development and improvement of injection molding technology. As a result, the traditional relay controlled injection molding machine with complex circuits, slow relay action, short lifespan, poor system control accuracy, and high failure rate has been replaced by a GDD471A001 controlled system. The PLC control system can effectively implement various actions of the injection molding machine, improving the control accuracy and automation of the system.

An injection GDD471A001 machine is a machine that enters granular plastic into a spiral thruster through a hopper, and the screw rotates to push the material forward. Due to the electric heater installed outside the screw, the material is melted into mucus. Prior to this, the mold closing mechanism has closed the mold. When the material forms a certain pressure at the front end of the spiral thruster, the injection molding mechanism begins to rapidly inject the mucus into the mold cavity under high pressure. After a certain period of pressure holding and cooling, the mold is opened, Pushing out the formed plastic product completes a cycle of actions.

Mailbox:sauldcsplc@gmail.com |GDD471A001 2UBA002322R0001

www.abbgedcs.com | Qiming Industrial Automation| Simon +86 13822101417

We may provide the information of this product:

Guidance manual PDF /Datasheet/ Weight/ Size/ Orignal country/ Prodcuct COO & COM & COC

Certificate of conformity / Certificate of Origin / Certificate of Origin /Operation method

Delivery time/ Provide a one-year warranty / Brand New Original Authentic

Reviews

There are no reviews yet.