PFTL201C-50KN | ABB | Measure roller rotation

¥8,021.00

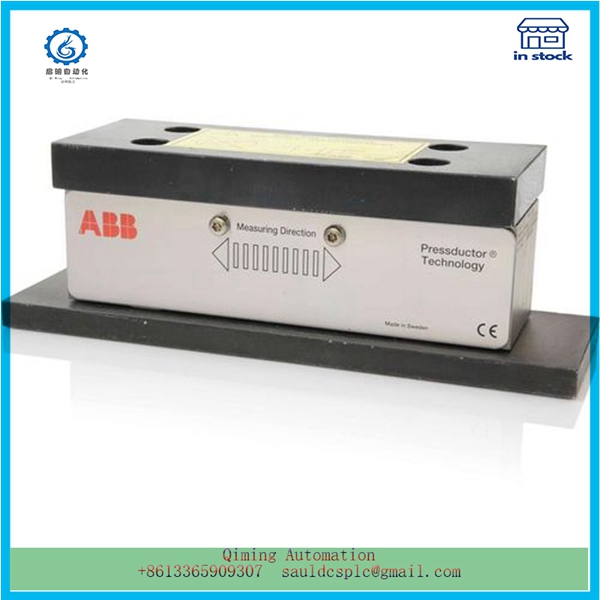

Module Number: PFTL201C-50KN

Product staus: Discontinued

Delivery time: In stock

Sales country: All over the world

Product situation: New or Used

Contact me: Sauldcsplc@gmail.com +8613822101417 SIMON

Have a good day! Thanks for watching my website!

Description

PFTL201C-50KN | ABB | Measure roller rotation

- .Many products are not yet on the shelves please contact us for more products

- .If there is any inconsistency between the product model and the picture on display, the model shall prevail. Contact us for the specific product picture, and we will arrange to take photos in the warehouse for confirmation

- .We have 16 shared warehouses around the world, so please understand that it can sometimes take several hours to accurately return to you. Of course, we will respond to your concerns as soon as possible

PFTL201C-50KN initialization is to prepare the chip for normal operation. Firstly, the system clock needs to be initialized, doubling the operating frequency from 8 M (external 8 M quartz crystal) to 72 M, then initializing the read and write permissions of the internal FLASH, and finally enabling the use of external clock on the bus. Enable peripheral timer 3 and enable PWM function.

As shown in Figure 1, the PFTL201C-50KN needs to process two external input signals. One is to measure the angular velocity, which can be obtained by measuring the time it takes for the roller to rotate one revolution. Here, external interrupts and timer 2 interrupts are enabled. When the roller rotates, the teeth on the shaft will cause the angular velocity meter to feedback a rising edge to the controller. When the next rising edge arrives, we can use timer 2 to obtain the time it takes for two rising edges to pass, thereby calculating the angular velocity of the roller. After giving the diameter of the roller, the PFTL201C-50KN velocity of the roller can be further calculated; The second is to measure tension, and to correctly use the peripheral ADC of the STM32 controller, the first step is to configure the corresponding GPIO pins connected to the hardware into analog input mode. Configure the working modes of ADC and DMA, and use the DMA function to transfer the converted digital quantity to a fixed register, facilitating subsequent mathematical operations.

Mailbox:sauldcsplc@gmail.com |PFTL201C-50KN

www.abbgedcs.com | Qiming Industrial Automation| Simon +86 13822101417

Reviews

There are no reviews yet.