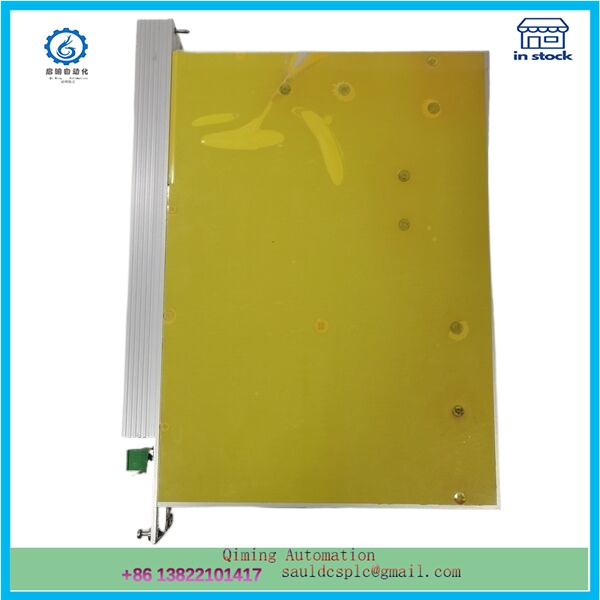

SAACKE F-OSA BURNER Control UNIT 143200

¥4,140.00

🔔Module Number: 143200

⚠️Product status: Discontinued

🏚️Delivery time: In stock

🆕Product status: 100% new

🌍Sales country: All over the world

🥇Product situation: one year warranty

📮Contact me: Sauldcsplc@gmail.com

💬Wechat/Whatsapp :+86 13822101417

☀️Have a good day! Thanks for watching my website!

Description

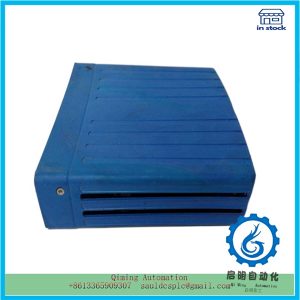

SAACKE F-OSA BURNER Control UNIT 143200 is a burner control unit produced by the German company SAACKE, specifically designed for industrial combustion systems to accurately control the operation of the burner, ensuring the efficiency, safety, and stability of the combustion process.

Product Features

high precision control

By adopting advanced microprocessor technology, precise control of the combustion process is achieved, including real-time adjustment of parameters such as fuel flow rate, air ratio, and ignition sequence.

Support combustion control for multiple fuel types (such as natural gas, fuel oil, etc.) to meet the needs of different industrial applications.

Safety protection function

Equipped with multiple safety protection mechanisms, such as flame monitoring, flameout protection, overtemperature alarm, and emergency shutdown function, to ensure that the burner can quickly cut off fuel supply in case of abnormal situations and prevent accidents from occurring.

Compliant with international safety standards such as EN, ATEX, etc., suitable for hazardous areas (explosion-proof design).

Modular design

Adopting a modular structure for easy installation, maintenance, and expansion. Users can choose different functional modules according to their actual needs to achieve customized configuration.

Support communication with upper computers (such as PLC, DCS) to achieve remote monitoring and data collection.

User friendly interface

Equipped with an intuitive operating interface, supporting local operation and remote control, making it convenient for users to set parameters and monitor status.

Provide fault diagnosis function, which can quickly locate and solve equipment faults.

application area

Industrial boilers: Steam boilers and hot water boilers used in industrial fields such as power plants, chemical plants, and paper mills.

Heat treatment equipment: such as furnaces, ovens, dryers, etc., used in industries such as metal processing and ceramic manufacturing.

Oil and natural gas: Used for heating and process control in facilities such as refineries and natural gas processing plants.

Other industrial applications, such as incinerators, hot air stoves, etc., are suitable for industrial processes that require high-temperature heating.

Technical parameters (refer to typical models)

Parameter description

Power supply voltage 220V AC ± 10%, 50/60Hz

Control accuracy ± 1%

Environmental temperature -20 ° C to+60 ° C

Protection level IP54 (can be customized according to requirements)

Communication interfaces such as RS485, Modbus RTU, Profibus DP, etc

Size standard 19 inch rack installation

advantage

Efficient and energy-saving: By optimizing the combustion process, reducing fuel consumption and emissions, and improving energy utilization efficiency.

High reliability: Industrial grade components and redundant design are used to ensure long-term stable operation of the equipment under harsh working conditions.

Easy to integrate: Supports seamless integration with existing automation systems, reducing renovation costs and time.

After sales service: SAACKE provides global technical support and spare parts supply to ensure that users have no worries.

precautions

Before installation and use, please carefully read the product manual to ensure compliance with local regulations and safety standards.

Regularly maintain and calibrate equipment to ensure optimal performance and safety.

If you need customized features or special configurations, please contact the SAACKE technical team.

Reviews

There are no reviews yet.